Tank Terminal Technology.

Flexible and Profitable – Pumping a Wide Variety of Oil Products With Just one Pump.

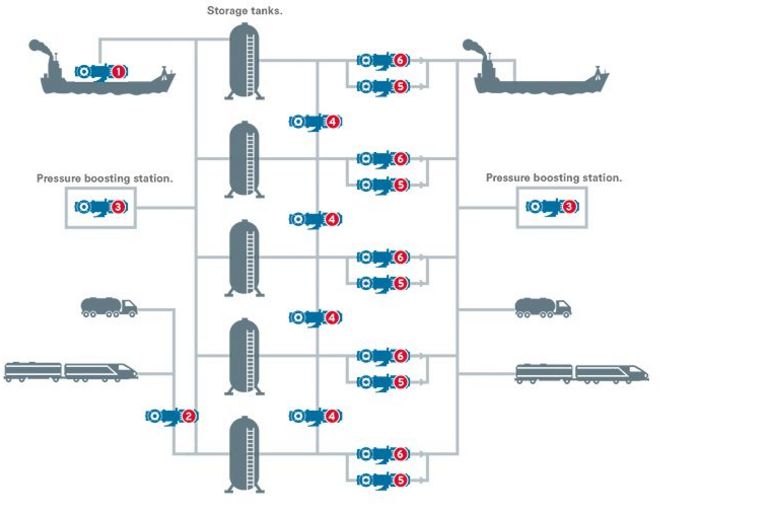

KRAL screw pumps are efficient and flexible, therefor they have a wide range of applications in tank farms. KRAL pumps can handle many different media with various qualities and viscosities, even with strongly varying backpressure and different suction behavior. The efficient operation of only one pump is profitable, one KRAL screw pump is suitable for all applications.

Fast goods turnover.

The storage and processing of petroleum products, chemicals and products with high viscosity require high-performance pumps. KRAL pumps guarantee reliable operation and fast goods turnover.

Conveying different media efficiently.

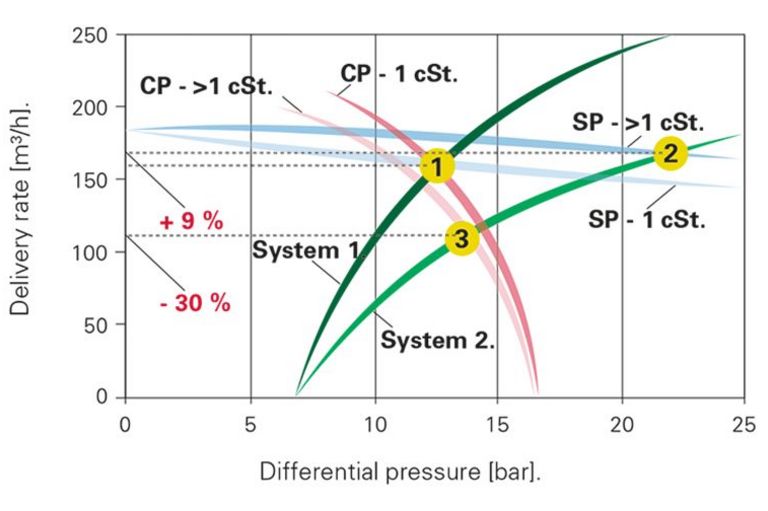

The viscosity of the products to be pumped is irrelevant for our pumps. We convey oil products with low viscosity (e.g. gas oil) as effective as products with high viscosity (e.g. bitumen). The flow rate characteristic remains the same, even with fluctuating pressures. When pumping highly viscous media, for example, a centrifugal pump quickly becomes inefficient or runs the risk of being damaged.

Long-lasting operation of the entire system.

KRAL screw pumps deliver with low pulsation, which is why other components such as pipelines are spared. Costs for system operation are reduced, since pipelines and hoses do not have to be replaced so often.

Energy savings.

Media do not have to be preheated or treated, that saves energy and operating time. Ships without heating equipment can also be unloaded. KRAL screw pumps are very flexible in terms of speed, can suck in the medium automatically with high force and have a constant flow rate even with different operating points.

Clear advantages compared to centrifugal pumps.

The standard "centrifugal pump" solution is increasingly being replaced by screw pump technology. This means that the disadvantages of centrifugal pumps, such as a lack of flexibility, no longer have to be compensated by the provision of several pumps. This saves costs. In contrast to centrifugal pumps, KRAL screw pumps cover a wide range of flow rates, pressures, temperatures and viscosities for almost all pumpable media. The medium flows through a screw pump at the same speed as in the pipe. This prevents damage and extends the service life of a screw pump.