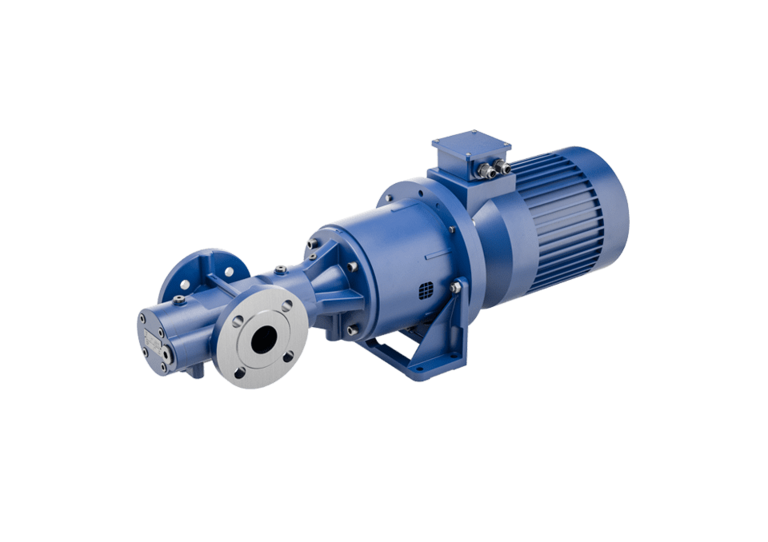

KRAL Screw Pumps with Magnetic Coupling.

100 % leak-free.

KRAL magnetic coupling screw pumps pay for themselves quickly: they are maintenance-free, hermetically sealed (no product leakage, no crystallization of the pumped media) and temperature-resistant up to 300 °C. Frequent replacement of mechanical seals is no longer necessary, a single installation of a magnetic drive screw pump is sufficient. This saves costs.

KRAL screw pumps with magnetic coupling.

Operation, materials, components.

- Delivery rate: 5 to 3,500 l/min.

- Max. differential pressure: 100 bar.

- Temperature range: -20 °C to 300 °C.

- Housing: Nodular cast iron EN-GJS-400, steel and aluminium.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

Leakage-free and clean.

Critical fluids containing substances endangering the health or the environment should not leak to the atmosphere. In contrast to conventional shaft seals, KRAL screw pumps with magnetic coupling are hermetically sealed by the integrated containment can. People and the environment are not endangered.

Can be used up to 300 °C.

Thermal distortion and the temperature limits of elastomeric sealing elements restrict the use of screw pumps in high temperature applications. If temperatures up to 300 °C are handled, KRAL screw pumps with magnetic coupling are the right choice.

Reduced lifecycle costs.

Spare parts and maintenance costs for mechanical seals increase the life cycle costs. Mechanical seals in KRAL screw pumps have a high technological standard. Even during proper operation, however, they are still a wearing part. KRAL screw pumps with magnetic coupling are maintenance-free and pay for themselves after just three years.

Protection of delivery medium.

With conventional seals, oxygen from the atmosphere may diffuse through the sealing gap into the fluid. When the fluid crystallizes from contact with oxygen, the process is interrupted and expensive plant shutdowns can result. KRAL screw pumps with magnetic coupling are hermetically sealed and protect the integrity of the fluid.

Favourable price.

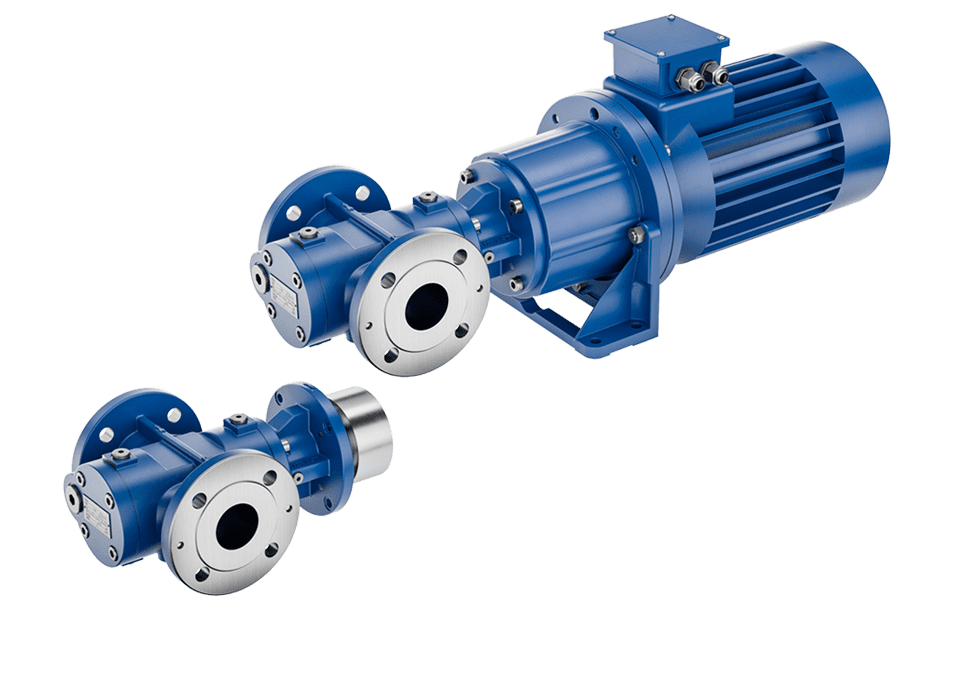

A magnetic coupling must transmit high torques and therefore requires very strong or many magnets. It can therefore become large and expensive. Not so with KRAL: When developing the magnetic coupled screw pumps, technical optimization was just as important as the cost aspect. The result: the screw pumps and magnetic coupling are optimally matched to each other, and the magnetic coupling pumps can be offered at an attractive price/performance ratio.

Overload protection.

If the operating limits are exceeded, the screw pumps may become damaged. Solids in the fluid can lead to blockages and damage the screw and the housing. In most cases, the product produced is not to specification, and the screw pumps must be replaced. If the decoupling is controlled, and the screw pumps stop, the screw pumps and magnetic coupling will suffer no damage. The magnetic coupling can prevent consequential damage.

Your advantages.

- Leak-free – no collection of residues.

- Wear-free - no maintenance.

- Hermetically sealed - no leakage of liquid.

- No plant standstill due to oxygen ingress.

- Temperature resistance up to 300 °C.

- High flow rates for all motor sizes.

- Rapid amortisation of the investment.

- Max. differential pressure: 100 bar.

- For many different applications – as you can see in our product catalog or on our website pump overview.

| Technical data | 5-42 | 55-118 | 160-275 | 370-450 | 550-660 | |

|---|---|---|---|---|---|---|

| Qth (1450 min-1, 0 bar) | l/min | 5-43 | 59-119 | 166-282 | 368-448 | 543-668 |

| Pressure | bar | 16 | 16 | 16 | 16 | 16 |

| Temperature | °C | 300 | 300 | 300 | 300 | 300 |

| Viscosity* | mm²/s | |||||

| min. | 2 | 2 | 2 | 2 | 2 | |

| max. | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | |

| Speed* | min-1 | |||||

| 50 Hz | 2,900 | 2,900 | 2,900 | 2,900 | 1,450 | |

| 60Hz | up to | 3,500 | 3,500 | 3,500 | 3,500 | 1,750 |

| Inlet pressure | bar | 16 | 16 | 16 | 16 | 16 |

*Please ask for other data. Technical data, dimensions and weights apply for the K series. For higher pressures of up to 100 bar and flow rates up to 2,900 l/min, please provide application information for the L and C series.

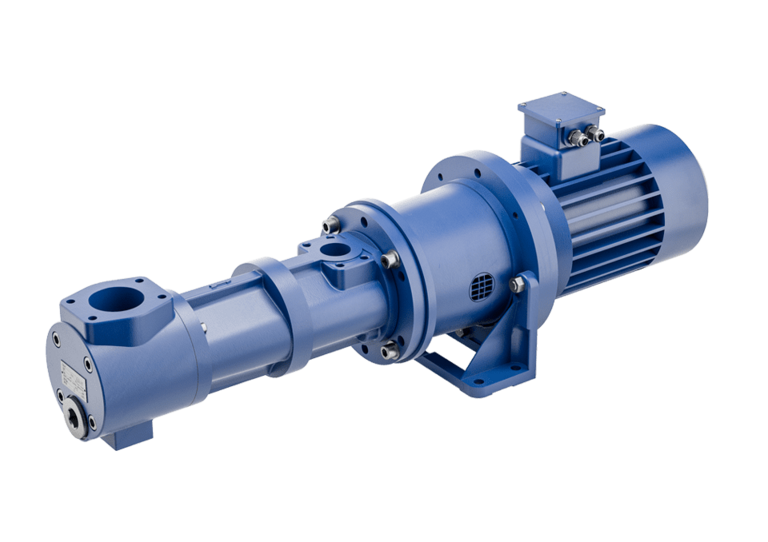

The right choice if the installation area is narrow or if there is not enough available space for large pumps.

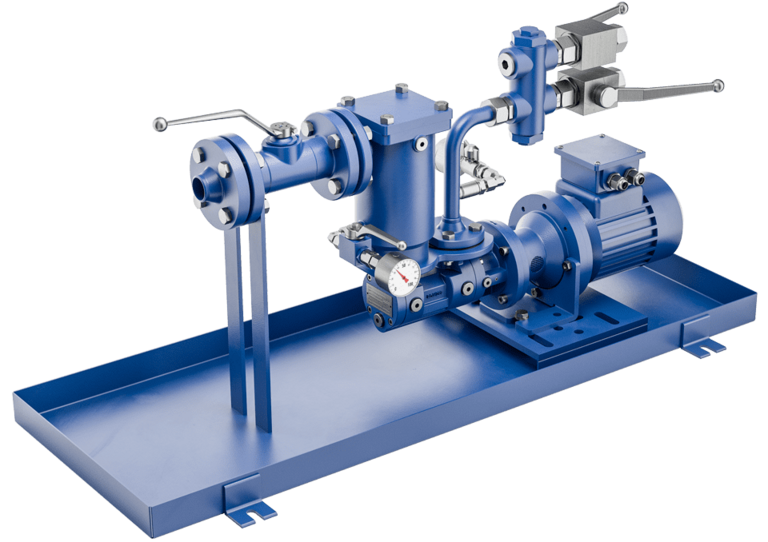

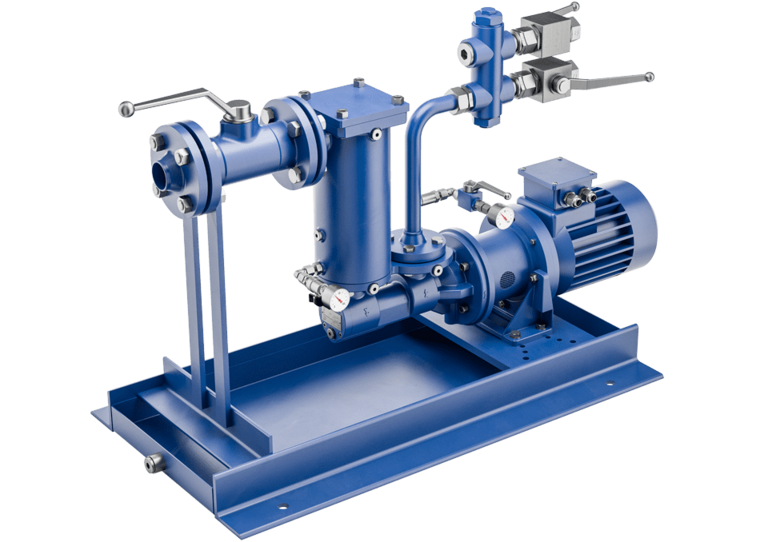

The single pump station EKL11/EKS11 consist of a screw pump K series with built-in safety valve, largely sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility. More options on request.

The single pump station EKL12/EKS12 consist of a screw pump K series with built-in safety valve, largely sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator. More options on request.

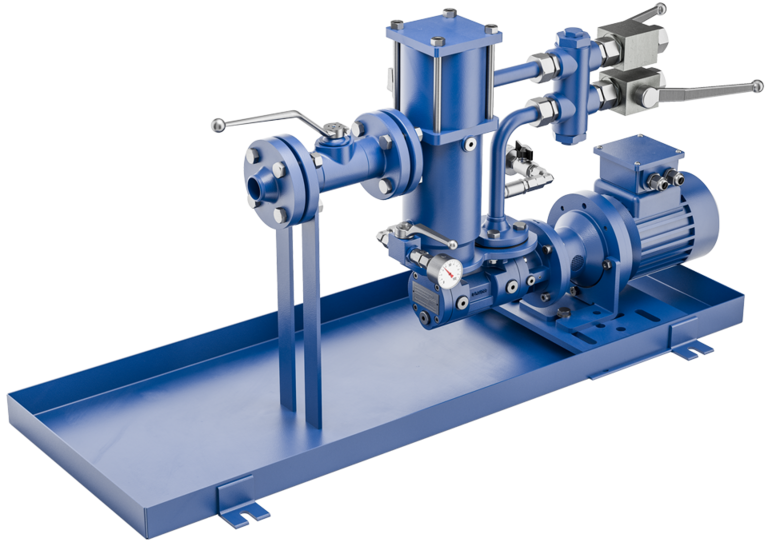

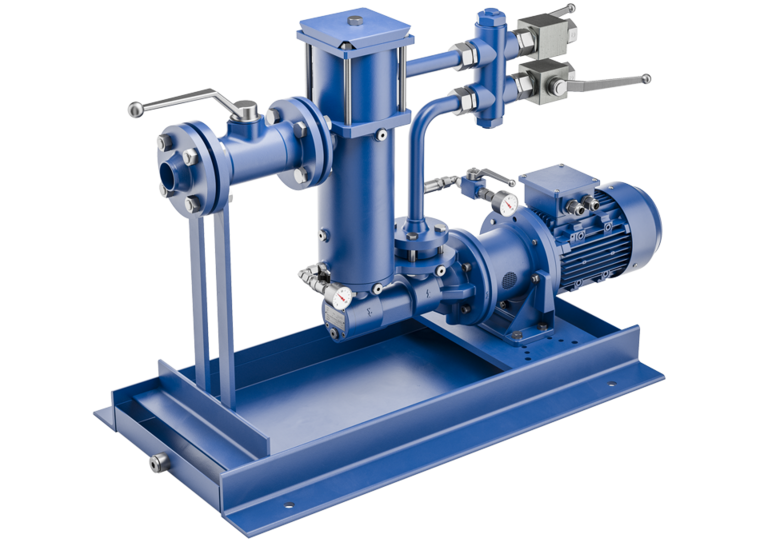

The single pump station EKL13/EKS13 consist of a screw pump K series with built-in safety valve, largely sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator and a gas / air separator. More options on request.

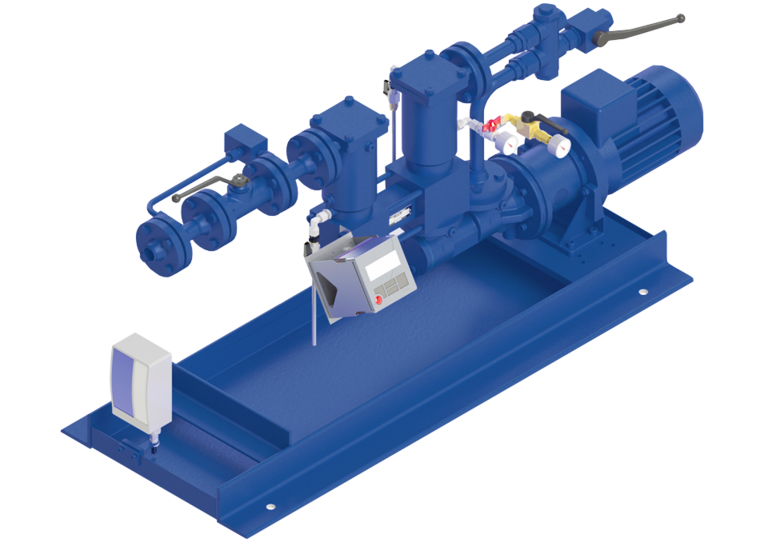

The single pump station EKL14 consist of a screw pump K series with built-in safety valve, largely sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator, a gas / air separator and a KRAL flowmeter. More options on request.

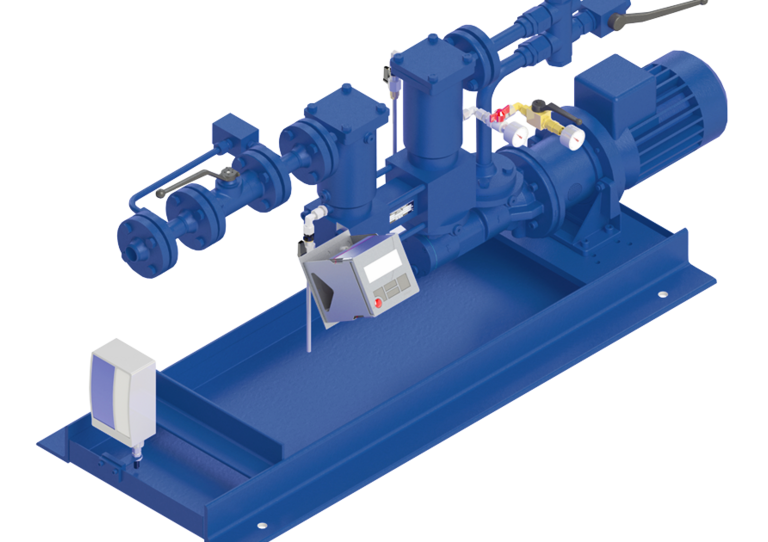

The single pump station ELL11/ELS11 consist of a screw pump L series with built-in safety valve, largely sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility. More options on request.

The single pump station ELL12/ELS12 consist of a screw pump L series with built-in safety valve, largely sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator. More options on request.

The single pump station ELL13/ELS13 consist of a screw pump L series with built-in safety valve, largely sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator and a gas / air separator. More options on request.

The single pump station ELL14 consist of a screw pump L series with built-in safety valve, largely sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator, a gas / air separator and a KRAL flowmeter. More options on request.

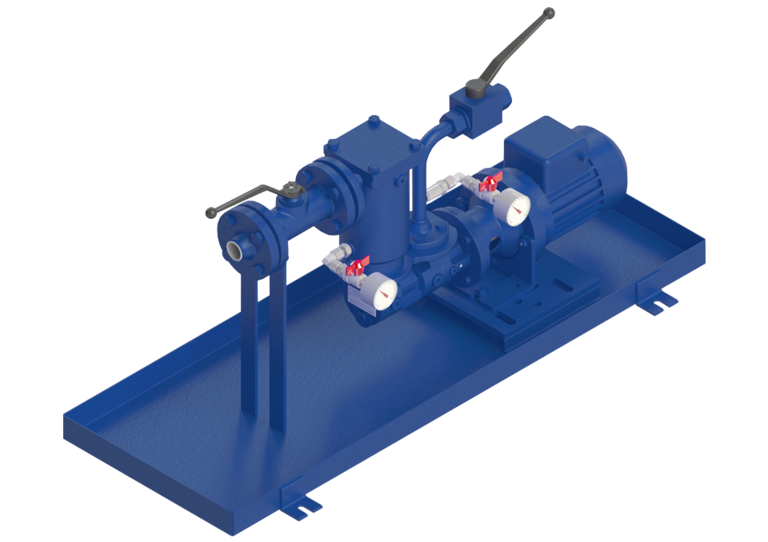

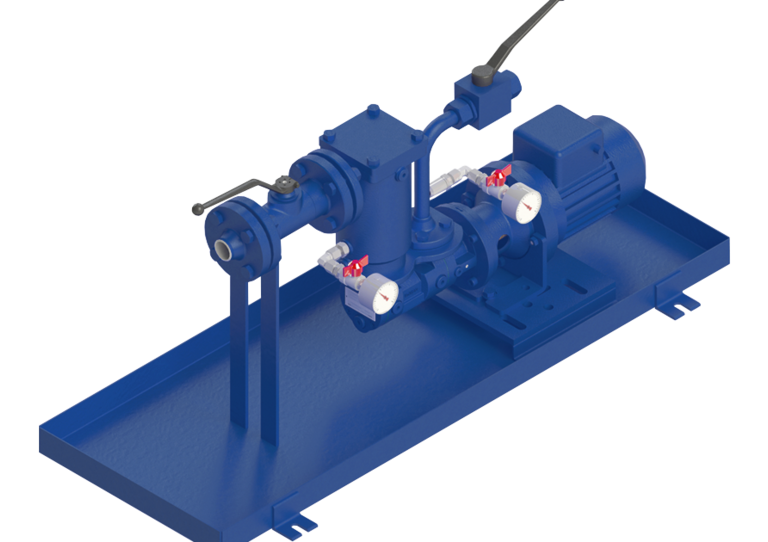

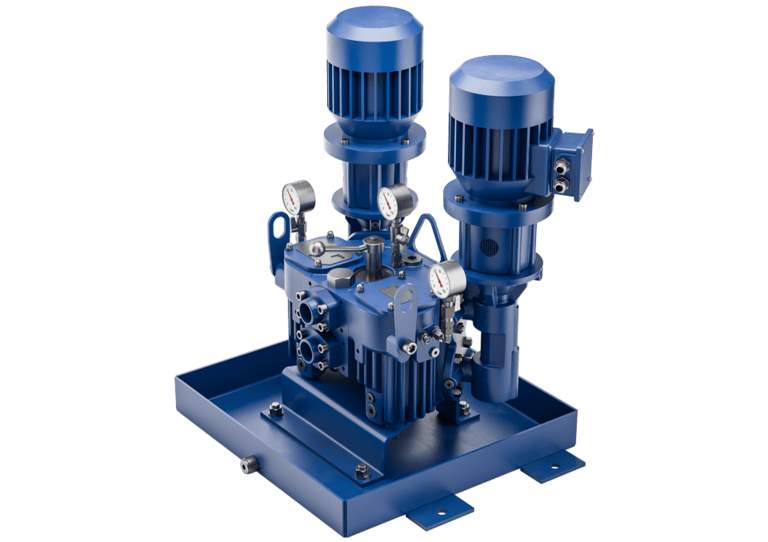

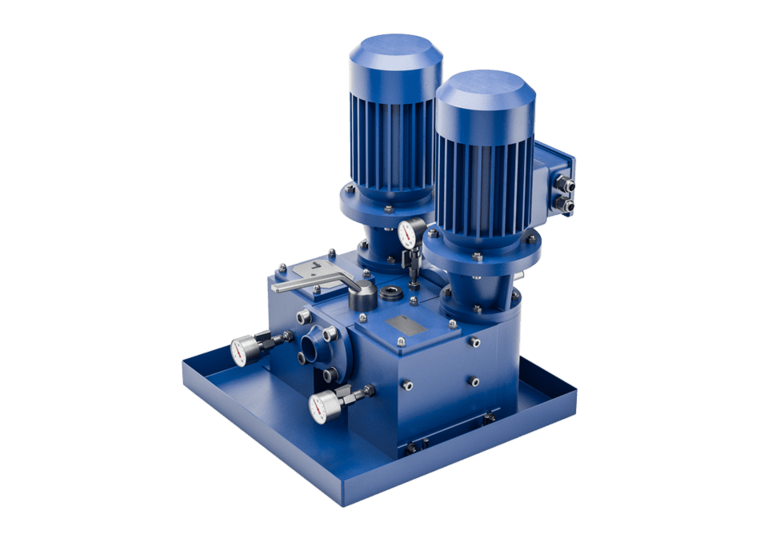

The compact double stations DKC and DLC consist of two screw pumps, station block, hoisting eye, suction-side pressure gauge, strainer cover, pressure-side pressure gauge, reversing valve lever, vent valve, pressure connection and suction connection. More options and magnetic coupling on request.

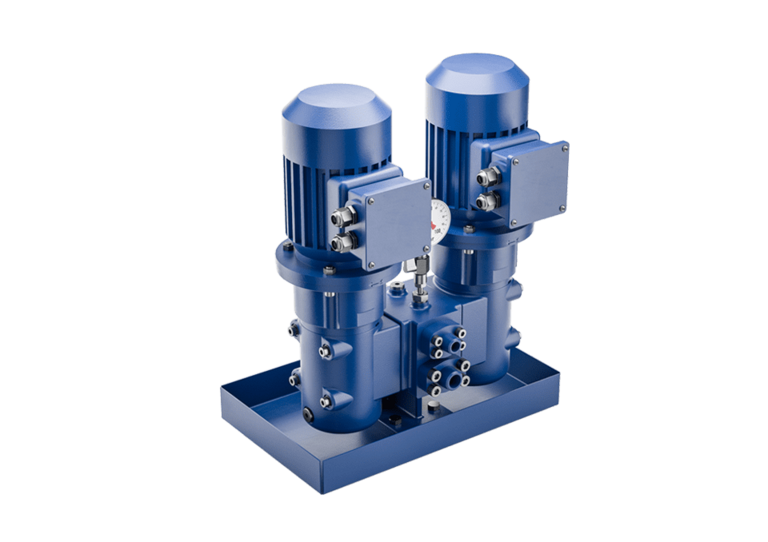

The double stations DS1, DS3, DS4, DL3, DL4 consist of two screw pumps , two strainers, two non return valves, overflow valve, two lockable vacuum gauges, lockable pressure gauge, oilpan and one lever control with counter flanges. More options and magnetic coupling on request.

The low pressure double station DL2 consist of two screw pumps, two strainers, two non return valves, overflow valve, lockable pressure gauge, oilpan and lever control with counter flanges. More options and magnetic coupling on request.