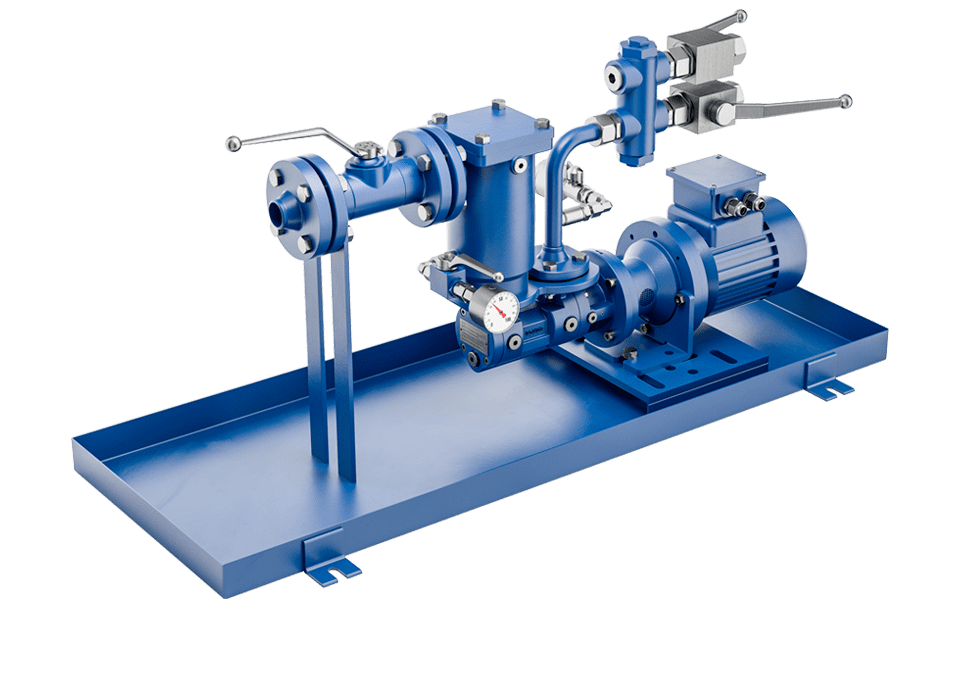

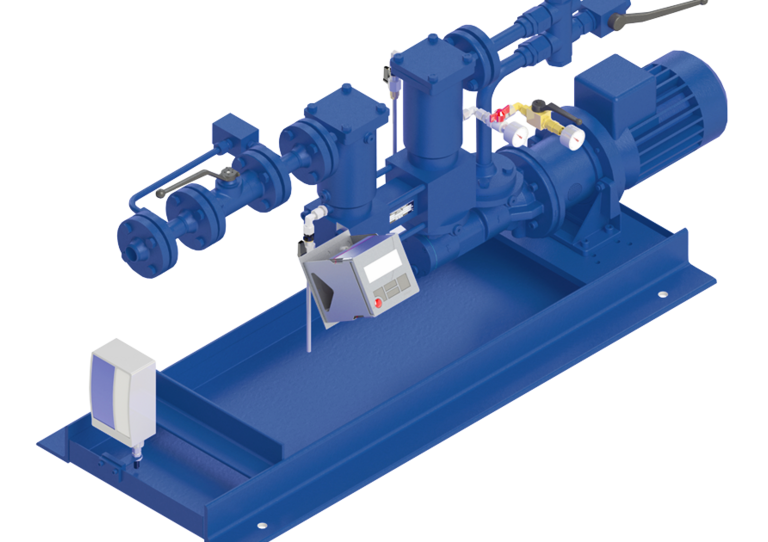

KRAL Oil Burner Pump Stations EK / EL.

Oil burner pump as complete station with additional functions.

These positive displacement pump stations combine all the advantages of the KRAL screw pumps K and L with additional functions for smooth and user-friendly operation. KRAL screw pumps convey highly efficient lubricating fluids, are low-wear, very compact and space-saving.

Operation, materials, components.

- Delivery rate: 5 to 280 l/min.

- Max. differential pressure: 40 bar.

- Temperature range: -20 °C to 180 °C.

- Housing: Nodular cast iron EN-GJS-400.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

- For viscous fluids up to 7,000 mm²/s.

The functions of the oil burner supply station of KRAL with K or L series screw pumps can be expanded individually, for example with:

- Pressure regulation

- Degassing

- Flow metering

- Filter

- Gas / air separator.

The mounted display instruments can swivel. Left- or right-handed installation can be set up individually at the site.

KRAL offers the optimal solution for every customer requirement. Just ask us, we have probably solved a similar problem already!

- Technical data.

EK series.

Technical data 5-10 15-26 32-55 Qth (1450 min-1, 0 bar) l/min 5-10 15-26 32-58 Max. pressure at pressure flange bar 6 6 6 Temperature max. pumped liquid °C with radial shaft seal NBR 80 80 80 with radial shaft seal FKM 150 150 150 with mechanical seal standard 150 150 150 with mechanical seal hard material 180 180 180 Viscosity mm²/s min. 1.1 1.1 1.1 max. 7,000 7,000 7,000 Max. pressure at suction flange bar with radial sealing ring 6 6 6 with mechanical seal standard 6 6 6 with mechanical seal hard material 6 6 6 EL series.

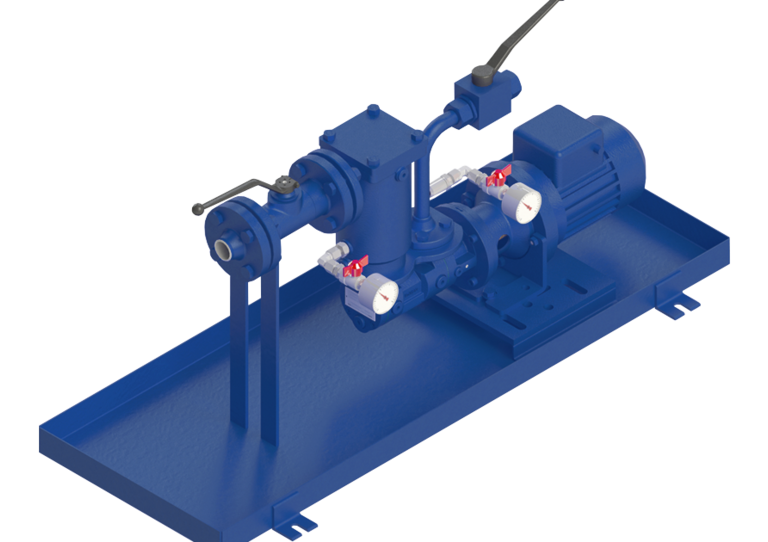

Technical data 5-10 15-26 32-54 Qth (1450 min-1, 0 bar) l/min 5-10 15-26 32-57 Max. pressure at pressure flange bar 40 40 40 Temperature max. pumped liquid °C with radial shaft seal NBR 80 80 80 with radial shaft seal FKM 150 150 150 with mechanical seal standard 150 150 150 with mechanical seal hard material 180 180 180 Viscosity mm²/s min. 1.1 1.1 1.1 max. 7,000 7,000 7,000 Max. pressure at suction flange bar with radial sealing ring 6 6 6 with mechanical seal standard 6 6 6 with mechanical seal hard material 6 6 6 - Models.Single pump station EKL11/EKS11.

For viscosity values from 1.1 to 7,000 mm²/s. Consists of a K series screw pump with built-in safety valve, large sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility. More options on request.

Single pump station EKL12/EKS12.

Same as EKL11/EKS11, but in addition with built-in safety valve, large sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator. More options on request.

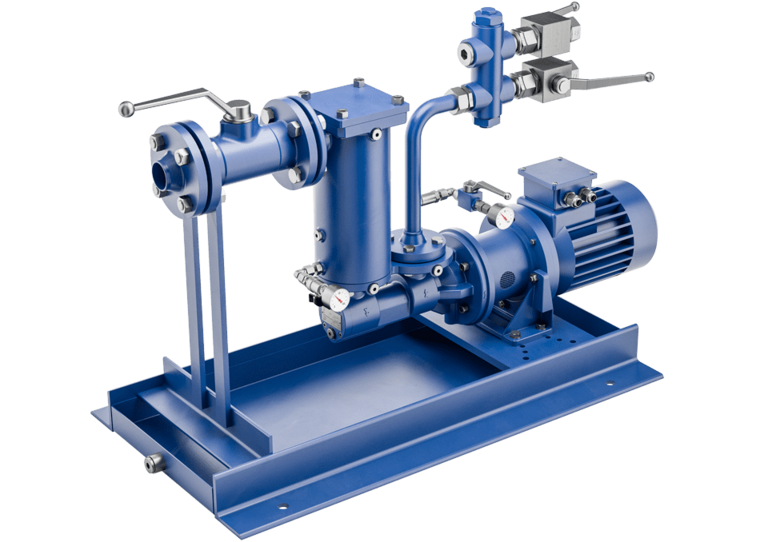

Single pump station EKL13/EKS13.

Same as EKL11/EKS11, but in addition with built-in safety valve, large sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator and a gas / air separator. More options on request.

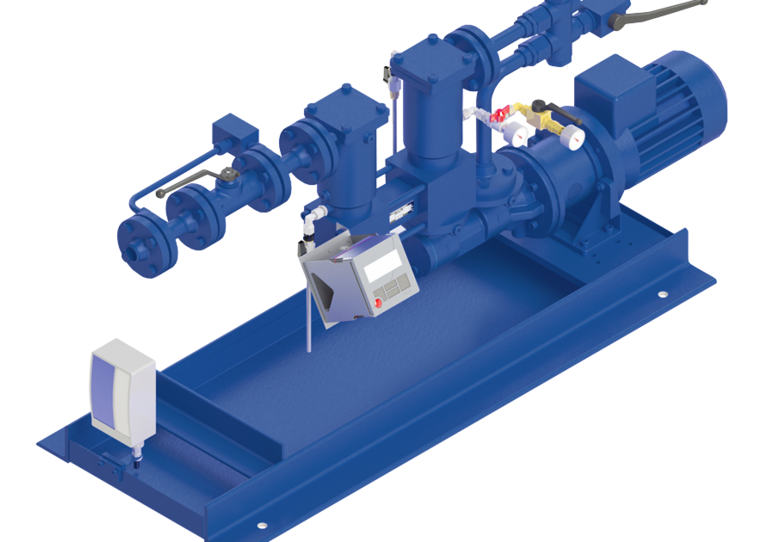

Single pump station EKL14.

Same as EKL11, but in addition with built-in safety valve, large sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator, a gas / air separator and a KRAL flowmeter. More options on request.

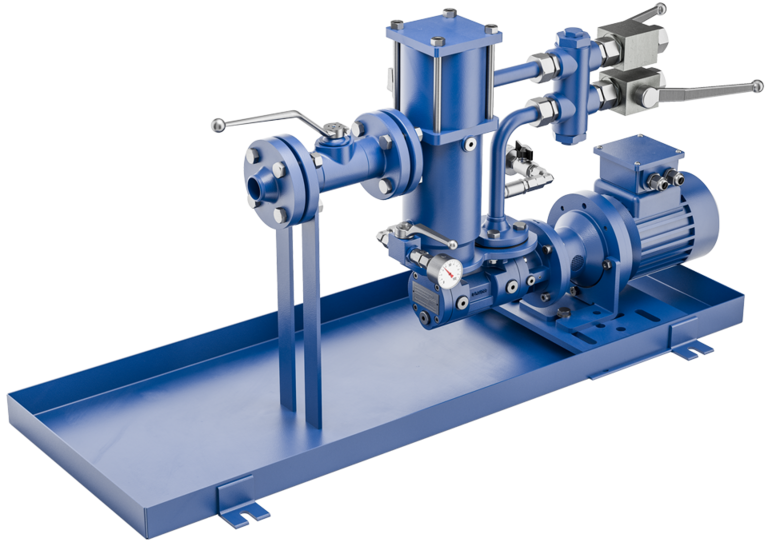

Single pump station ELL11/ELS11.

For viscosity values from 1.1 to 7,000 mm²/s. Consists of a L series screw pump with built-in safety valve, large sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility. More options on request.

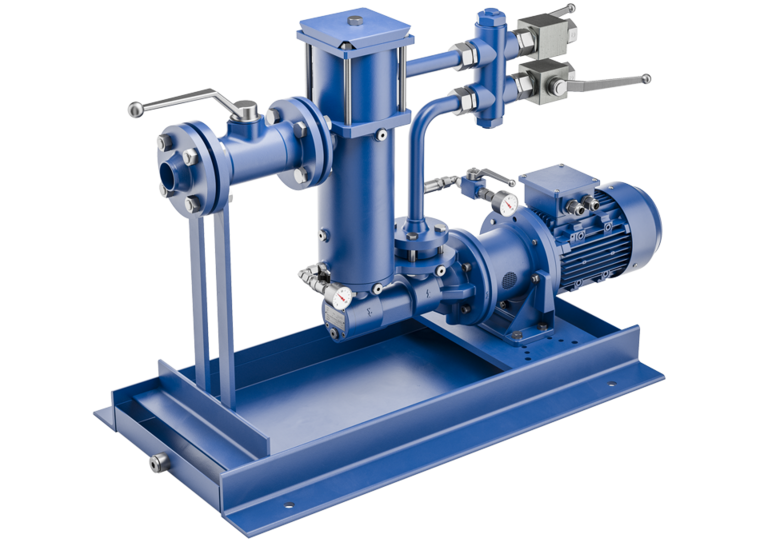

Single pump station ELL12/ELS12.

Same as ELL11/ELS11, but in addition with built-in safety valve, large sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator. More options on request.

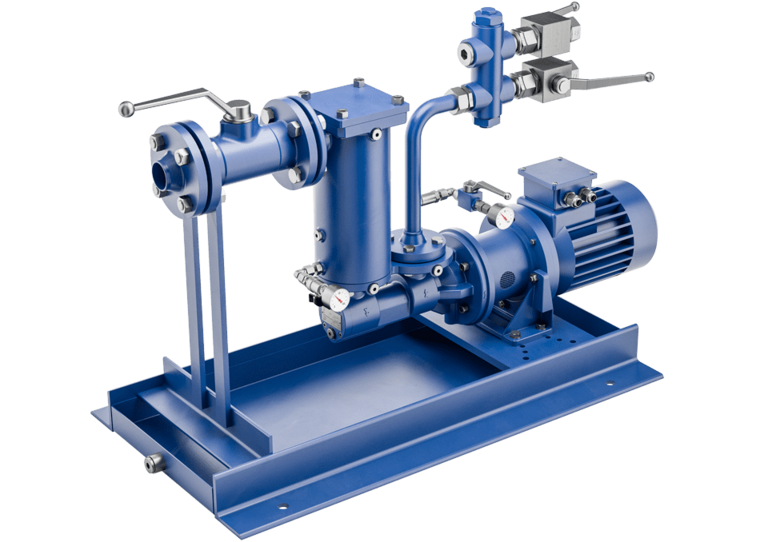

Single pump station ELL13/ELS13.

Same as ELL11/ELS11, but in addition with built-in safety valve, large sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator and a gas / air separator. More options on request.

Single pump station ELL14.

Same as ELL11, but in addition with built-in safety valve, large sized strainer and delivery ball valves as well as pressure and vacuum gauges with shut-off facility with an additional pressure regulator, a gas / air separator and a KRAL flowmeter. More options on request.

- NPSH

- Operating instructions.