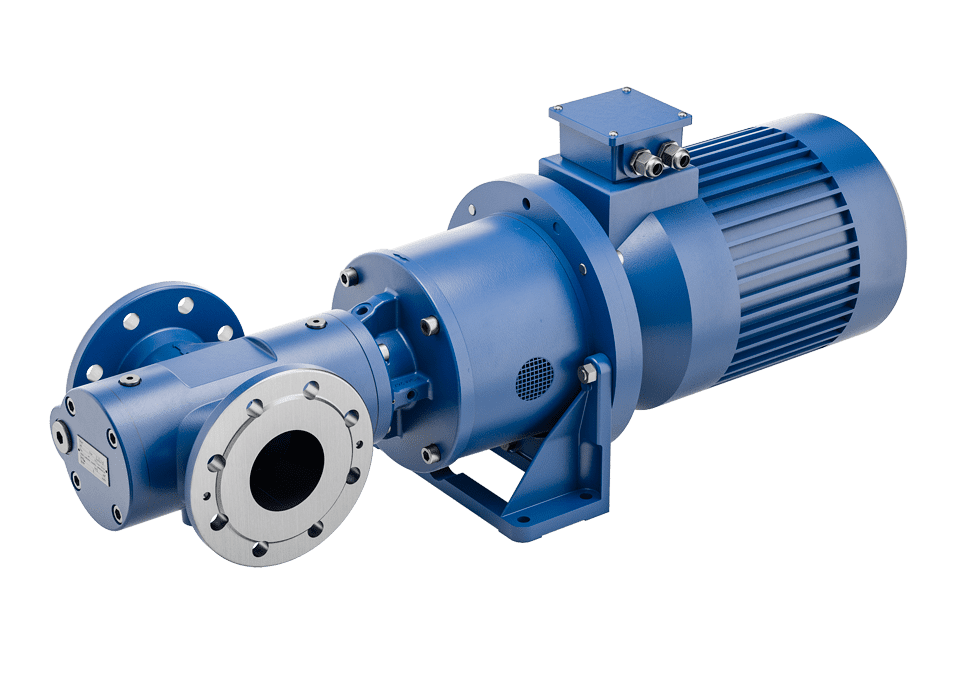

KRAL K Series Screw Pumps.

Universally applicable screw pump.

For pumped media up to 16 bar.

One of our best-selling products: compact and universally applicable, reliable and efficient. These are the KRAL screw pumps of the K series. Their housing is made from nodular cast iron and they have a sealed, lifetime-lubricated, service-free external bearing. The KRAL K series screw pumps are approved for use on board ships.

Operation, materials, components.

- Delivery rate: 5 to 2,900 l/min.

- Delivery rate KFT: 5 to 510 l/min.

- Max. differential pressure: 16 bar.

- Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

- Viscosity: 10,000 mm²/s.

- Housing: Nodular cast iron EN-GJS-400.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, fluid media or steam.

Advantages of the KRAL K series screw pumps.

Suitable for many applications, very compact, robust, flexible, excellent price-performance ratio. Perfectly adequate for pressures up to 16 bar. All products of the K series have an internal safety valve and can be ordered with DIN flanges in inline arrangement (except KFT and KFN). Like all KRAL screw pumps, the pumps of the K series are self-priming, deliver with low-pulsation and, in contrast to other functional principles, can be easily regulated.

Stop coupling damage.

With some liquids, residue can build up, which may cause the pump to fail. A typical spot for residue to build up is at the mechanical seal. The residue damages the ball bearing, which runs hot, melts the elastomeric ring and damages the coupling. With the K series screw pump, there is a weep hole next to the mechanical seal, to prevent the fluid from collecting and building up as residue.

KRAL offers the advanced quality of SiC mechanical seals, which contain graphite, as a solid lubricant to reduce the coefficient of friction in dry running conditions. The O rings with high fluorine content are suitable for higher temperatures and are chemically stable. The K series screw pump offers innovative seal concepts. A proven selection of radial rotary shaft seals, mechanical seals and a hermetically sealed magnetic coupling are available as standard. A robust and compact design rounds off the profile.

- Technical data.

Technical data 15-42 55-118 160-275 370-450 550-660 851-1301 1500-1700 2200-2900 Qth (1450 min-1, 0 bar) l/min 15-42 55-118 160-275 370-450 550-660 851-1301 1500-1700 2200-2900 Max. pressure at pressure flange bar K 16 16 16 16 16 16 16 16 KFT 16 16 16 Temperature °C with NBR rotary lip seal 90 90 90 90 90 90 90 90 with FKM rotary lip seal 150 150 150 150 150 150 150 150 with mechanical seal standard 150 150 150 150 150 150 150 150 with mechanical seal hard material 180 180 180 180 180 180 180 180 with magnetic coupling 300 300 300 300 300 300 300 300 Viscosity mm²/s min. 1.1 1.1 1.1 1.4 1.4 1.4 1.4 1.4 max. 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 Max. pressure at suction flange bar with rotary lip seal 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 with mechanical seal standard 6 6 6 6 6 6 6 6 with mechanical seal hard material 10 10 10 10 10 10 10 10 with magnetic coupling 10 10 10 10 10 10 10 10 - Models.

- NPSH.

- Operating instructions.