KRAL C Series Screw Pumps.

For pressures of up to 100 bar.

Efficient, self-priming high-pressure pump up to 100 bar.

Pump solution for high pressures at an excellent price-performance ratio. With KRAL screw pumps of the C series you buy high-pressure pumps with all the advantages of our KRAL pumps K and L: robust, low-wear, flexible, space-saving, durable and much more. Compared to other pump solutions, KRAL screw pumps convince with highest reliability, even under different operating conditions the screw pumps are highly efficient.

Due to the wide range of possible applications, we offer the KRAL C series as standard in the CK, CL and CG series. The main components of these pumps are all the same, the differences lie in the individual details, matched to the requirements in different applications (see detailed description below).

Application examples: Injection pumps, feed pumps, burner pumps, jacking pumps, transformer oil cleaning pumps, hydraulic pumps and generally all applications in which efficient, reliable high-pressure pumps for lubricating media are required.

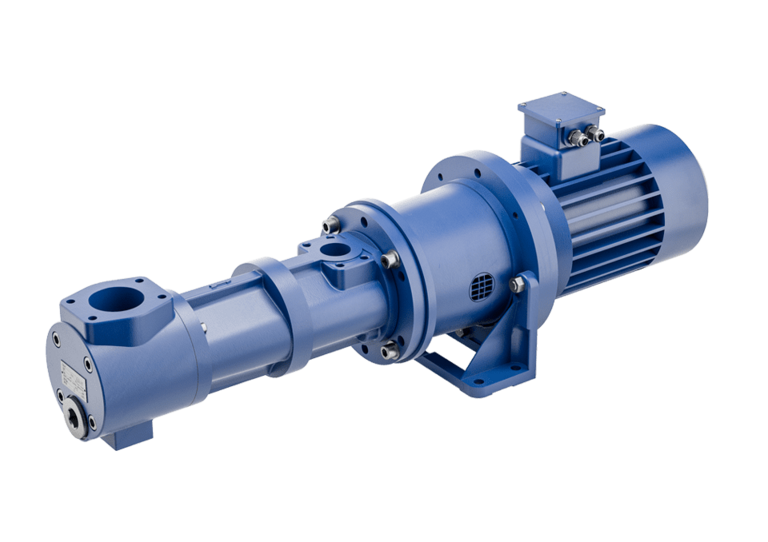

KRAL CK series.

High-pressure pump for various media, easy to install.

The KRAL screw pump of the CK series is an extremely compact and cost-effective solution for high-pressure applications. It is also the best-selling screw pump line of the KRAL C series. Standardized pump / motor brackets made of aluminum are used for the CK pump - which is reflected in the favorable price and easy installation.

The screw pump of the CK series with its short shaft, radial shaft seal and internal bearings is a preferred solution in many applications.

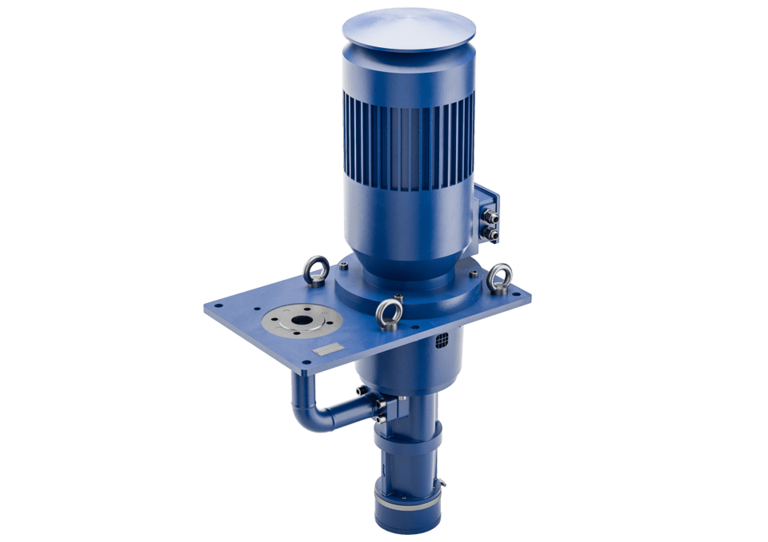

KRAL CL series.

Reliable pump at high pressure.

The KRAL screw pump of the CL series is a high-pressure pump with a longer main spindle than the CK screw pump has. It can also be equipped with various shaft seals and external bearings. The KRAL CL series is often used as a horizontal or vertical foot pump or flange mounted pump as well as in tank-vertical arrangements.

KRAL screw pumps of the CL series are also used as cartridge (insert) pump for KRAL screw pumps of the CG series (see below).

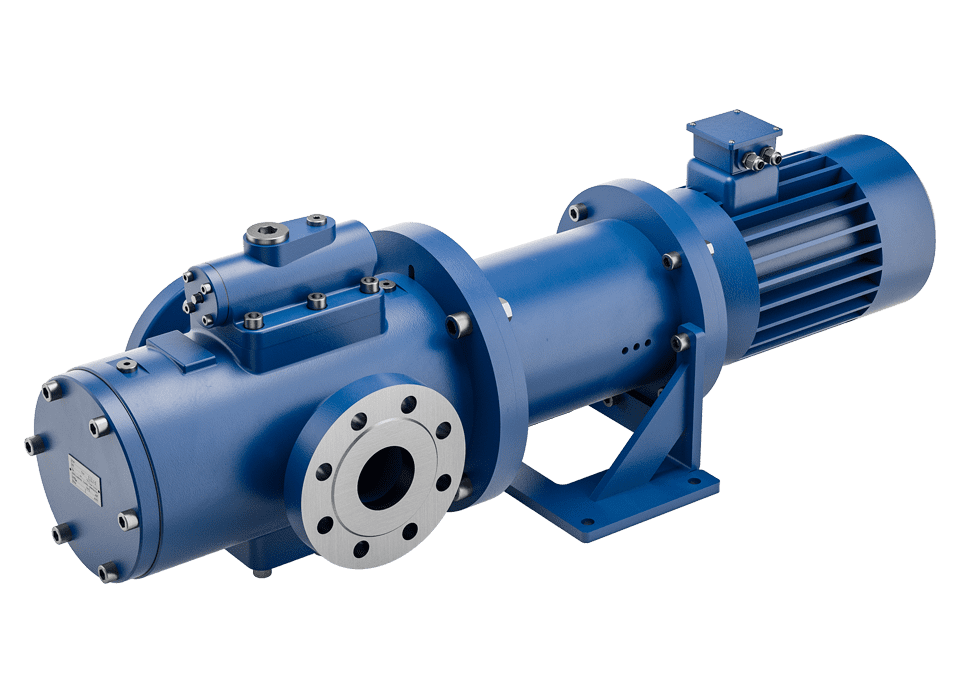

KRAL CG series.

Extremely flexible high-pressure pump.

The KRAL screw pump of the CG series is used as a cartridge pump (insert pump) for the CL series and is available with various housings, relief valves and connections. The housing is available in cast iron or steel. We also manufacture the KRAL screw pumps of the CG series with heating jacket for high-viscosity media. The different housing options allow almost any location as well as many sizes and types of liquid connections.

The KRAL CG series - our flexible product for many different applications – as you can see in our product catalog or on our website pump overview.

Your advantages.

- Flow rates up to 3,550 l/min.

- Viscosity of 1,000,000 mm²/s.

- Pressure maximum up to 100 bar.

- A variety of housings, relief valves and connections.

- Housing in cast iron or steel available.

- Heating jacket for high-viscosity liquids.

- For almost any location, size and type of liquid connection.

- External overflow valve can be optionally attached.

- Technical data.

CK series

CK series.

Technical data CK 5-10 15-26 32-42 55-85 105-118 160-210 235-275 370-450 550-880 Qth (1.450 min-¹, 0 bar) l/min 5-10 15-26 32-42 55-85 105-118 160-210 235-275 370-450 550-880 Max. discharge pressure bar 100 70 70 70 70 70 70 70 40 Temperature °C with radial shaft seal NBR

with radial shaft seal FKM90

15090

15090

15090

15090

15090

15090

15090

15090

150Viscosity mm²/s min. 1.1 1.1 1.1 1.1 1.1 1.1 1.4 1.4 1.4 max. 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 Max. pressure at suction flange bar with radial shaft seal 10 10 10 10 10 10 10 10 10 CL series

CL series.

Technical data CL 5-10 15-26 32-42 55-85 105-118 160-210 235-275 370-450 550-880 Qth (1.450 min-¹, 0 bar) l/min 5-10 15-26 32-42 55-85 105-118 160-210 235-275 370-450 550-880 Max. discharge pressure bar 100 100 100 100 100 100 100 80 80 Temperature °C with stuffing box packing 80 80 80 80 80 80 80 80 80 with radial shaft seal 150 150 150 150 150 150 150 150 150 with mechanical seal - standard 150 150 150 150 150 150 150 150 150 with mechanical seal - hard material 180 180 180 180 180 180 180 180 180 with magnetic coupling 300 300 300 300 300 300 300 300 300 Viscosity mm²/s min. 1.1 1.1 1.1 1.1 1.1 1.1 1.4 1.4 1.4 max. 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 Max. pressure at suction flange bar with stuffing box packing 3 3 3 3 3 3 3 3 3 with radial shaft seal 10 10 10 10 10 10 10 10 10 with mechanical seal 30 30 30 30 30 30 30 30 30 with magnetic coupling 16 16 16 16 16 16 16 16 16 CG series

CG series.

Technical data CG 15-26 32-42 55-85 105-118 160-210 235-275 Qth (1.450 min-¹, 0 bar) l/min 15-26 32-42 55-85 105-118 160-210 235-275 Max. discharge pressure bar 100 100 100 100 100 100 Temperature °C with stuffing box packing 80 80 80 80 80 80 with radial shaft seal 150 150 150 150 150 150 with mechanical seal - standard 150 150 150 150 150 150 with machanical seal - hard material 180 180 180 180 180 180 with magnetic coupling 300 300 300 300 300 300 Viscosity mm²/s min. 1.1 1.1 1.1 1.1 1.1 1.1 max. 1,000,000 1,000,000 1,000,000 1,000,000 1,000,000 1,000,000 Max. pressure at suction flange bar with stuffing box packing 3 3 3 3 3 3 with radial shaft seal 10 10 10 10 10 10 with mechanical seal 30 30 30 30 30 30 with magnetic coupling 100 100 100 100 100 100 Technical data CG 370-450 550-880 851-951 1101-1301 1501-1701 2250-3550 Qth (1.450 min-¹, 0 bar) l/min 370-450 550-880 851-951 1101-1301 1501-1701 2250-3550 Max. discharge pressure bar 100 100 100 100 100 100 Temperature °C with stuffing box packing 80 80 - - - - with radial shaft seal 150 150 150 150 150 150 with mechanical seal - standard 150 150 150 150 150 150 with mechanical seal - hard material 180 180 180 180 180 180 with magnetic coupling 300 300 300 300 300 300 Viscosity mm²/s min. 1.4 1.4 1.4 1.4 1.4 1.4 max. 1,000,000 1,000,000 1,000,000 1,000,000 1,000,000 1,000,000 Max. pressure at suction flange bar with stuffing box packing 3 3 - - - - with radial shaft seal 10 10 10 10 10 10 with mechanical seal 30 30 30 30 30 30 with magnetic coupling 100 100 100 100 100 100 - Models.

- NPSH.

- Operating instructions.

![[Translate to USA:] screw_pumps_CGH_horizontal.jpg schraubenspindelpumpe baureihe CGH in horizontaler aufstellung](/fileadmin/_processed_/4/1/csm_baureihe-c-bauform-cgh_8e12a48add.png)