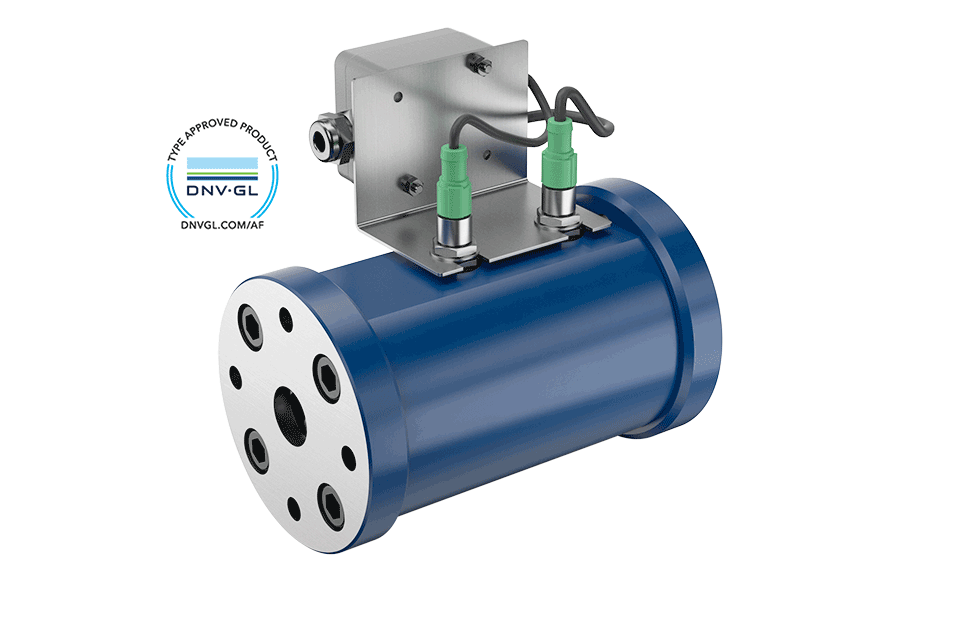

KRAL Flowmeters OMP Series.

Robust solution for flow measurement of diesel and heavy fuel oil.

The OMP series flowmeters are designed specifically for fuel consumption measurement for marine applications as well as others, and can be used in booster modules and burners.

A perfect combination of precision and robustness: Due to the precise measurement chamber volume, a broad range of measurements with a precision rate of 0.1 % can be achieved. Pipe bends and T-sections have no influence on the measurement accuracy or performance of the KRAL flow meter.

The extreme robustness is achieved by the spheroidal graphite iron housing, which provides optimal protection for the precisely manufactured screws. The screws of KRAL flowmeters quickly follow the changes of the fuel flow rate, the fuel pulses and may even change its flow direction briefly.

The measurement devices run with low friction, gentle and with minimal pressure loss. Long lifespan, resistance to pulsations in the media, and efficiency across the entire product life cycle are just a few of the benefits that KRAL flowmeter OMP offers.

Your benefits.

- KRAL flow meter suitable for Marine diesel oil (MDO), Marine gas oil (MGO), Heavy fuel oil (HFO) and further types of oil.

- High accuracy flow measurement of fuel flow and oil flow.

- Very robust and long life time meter.

- Low friction and minimal loss of pressure.

- Stabilization zones unnecessary.

- Easy installation.

- Suitable for harsh industrial conditions.

Technical data.

- Media: Chemically neutral, lubricating, clean, non-abrasive, diesel and heavy fuel oil.

- Flow direction detection: Second sensor range optional.

- Temperature measurement: Additional sensor optional.

- Sensor: PNP or Namur signal.

- Process fittings: DIN, ANSI, thread. Further connections upon request.

Materials.

- Housing: Spheroidal graphite iron.

- Screws: Nitrided steel.

- Bearings: Hybrid ball bearings.

- Sealing: FKM, other seal materials upon request.

| Technical data | OMP-13 | OMP-20 | OMP-32 | OMP-52 | |

|---|---|---|---|---|---|

| Nominal diameter | DN [mm] | 15 | 20 | 25/32 | 40 |

| DN [inch] | 1/2 | 3/4 | 1 | 1 1/2 | |

| Total length with DIN flange | [mm] | 115 | 125 | 180/190 | 240 |

| Weight with DIN flange | [kg] | 4 | 5 | 11/13 | 19 |

| Flow rate I/h | Qmax | 900 | 2,700 | 9,000 | 31,500 |

| Qnom | 600 | 1,800 | 6,000 | 21,000 | |

| Qmin | 6 | 18 | 60 | 210 | |

| Flow rate I/min | Qmax | 15 | 45 | 150 | 525 |

| Qnom | 10 | 30 | 100 | 350 | |

| Qmin | 0.1 | 0.3 | 1.0 | 3.5 | |

| Max. pressure | [bar] | 40 | 40 | 40 | 40 |

| Temperature | [°C] | -20 to +200 | -20 to +200 | -20 to +200 | -20 to +200 |

| Viscosity | [mm²/s] | 1 to 1x106 | 1 to 1x106 | 1 to 1x106 | 1 to 1x106 |

| Precision | of measurement value | ±0.1 % | ±0.1 % | ±0.1 % | ±0.1 % |

| Repeatability | ±0.01 % | ±0.01 % | ±0.01 % | ±0.01 % | |

| K-factor | K [P/I] | 1,214.0 | 321.0 | 78.0 | 17.73 |

| Frequency | f at Qnom [Hz] | 202 | 161 | 130 | 104 |