Signal detection via the pole wheel

Signal detection via the pole wheel

With this method, the impulse transmitter detects the impulses via a pole wheel, which is attached to the measurement screw. Based on specifications and need, pole wheels with differing numbers of poles can be used. This enables a significantly higher signal transfer resolution. Signal detection via the pole wheel is used when a high signal resolution is needed, e.g., with test and calibration benches or with the use of a flowmeter in the lower flow range.

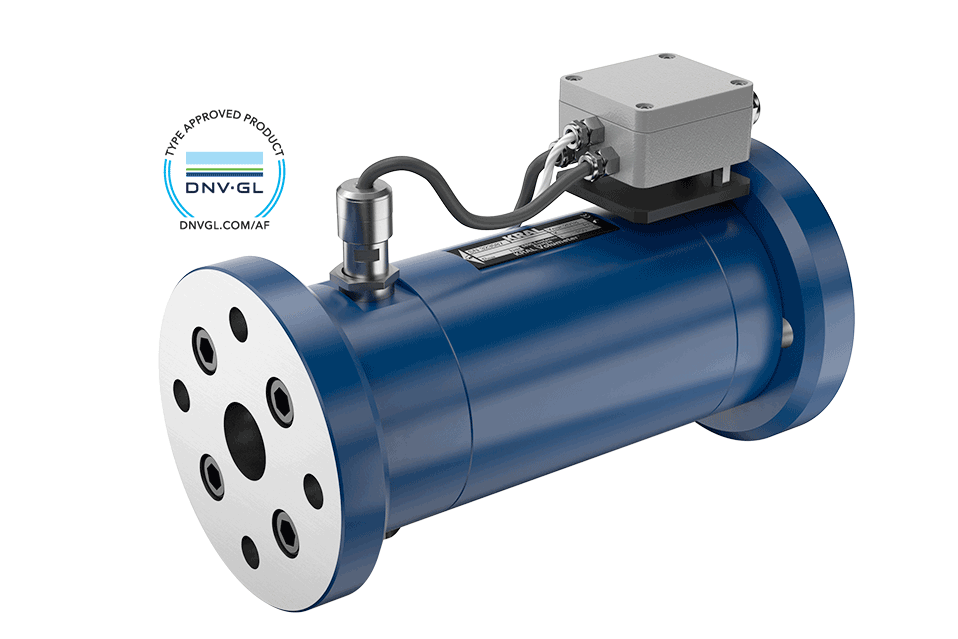

KRAL Flowmeters OMG Series.

Universal device for manifold application needs.

Due to their continuous ongoing development, the highly modular OMG series covers a broad range of applications. This series is therefore particularly suitable for manifold applications, such as mechanical engineering, chemical engineering and marine.

The flow meters OMG series also combines robustness with highest precision, characteristics for which KRAL flow meters are well-known worldwide. Due to the screw pump principle, all OMG series devices are very smooth-running and fast, and can follow quick, pulsation-related changes in flow rates. Due to their extremely robust construction, the OMG series provides optimal protection against external influences, such as system vibrations and mechanical stresses in harsh environments.

Your benefits.

- Wide range of applications which have a manifold need for flow measurement, such as mechanical engineering, chemical engineering and marine.

- High precision flow meter.

- Extremely robust.

- Stabilization zones unnecessary.

- Easy installation.

- Very smooth-running, follows any rapid fluctuations in the flow causes by pulsations

- Low friction and minimal loss of pressure.

Technical data.

- Media: Chemically neutral, lubricating, clean, non-abrasive.

- Flow direction control: Extended sensor range optional.

- Temperature measurement: Additional sensor optional.

- Sensor: PNP, Namur or Push-pull.

- Process fittings: DIN, ANSI, thread. Further connections upon request.

Materials.

- Housing: Spheroidal graphite iron.

- Screws: Nitrided steel.

- Bearings: Steel or hybrid bearings.

- Sealing: FKM. Other seal materials upon request.

| Technical data | OMG-13 | OMG-20 | OMG-32 | OMG-52 | OMG-68 | OMG-100 | OMG-140 | |

|---|---|---|---|---|---|---|---|---|

| Nominal diameter | DN [mm] | 15 | 20 | 25/32 | 40 | 50 | 100 | 150 |

| DN [inch] | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 4 | 6 | |

| Total length with DIN flange | [mm] | 145 | 185 | 255/265 | 285 | 340 | 460 | 610 |

| Weight with DIN flange | [Kg] | 6 | 6 | 13/15 | 21 | 31 | 77 | 190 |

| Flow rate I/h | Qmax | 900 | 2,700 | 9,000 | 31,500 | 63,000 | 180,000 | 450,000 |

| Qnom | 600 | 1,800 | 6,000 | 21,000 | 42,000 | 120,000 | 300,000 | |

| Qmin | 6 | 18 | 60 | 210 | 420 | 1,200 | 3,000 | |

| Flow rate I/min | Qmax | 15 | 45 | 150 | 525 | 1,050 | 3,000 | 7,500 |

| Qnom | 10 | 30 | 100 | 350 | 700 | 2,000 | 5,000 | |

| Qnom | 0.1 | 0.3 | 1.0 | 3.5 | 7.0 | 20 | 50 | |

| Max. pressure | [bar] | 250 | 250 | 250 | 160 | 100 | 40 | 40 |

| Temperature | [°C] | -20 to +200 | -20 to +200 | -20 to +200 | -20 to +200 | -20 to +200 | -20 to +200 | -20 to +200 |

| Viscosity | [mm²/s] | 1 to 1x106 | 1 to 1x106 | 1 to 1x106 | 1 to 1x106 | 1 to 1x106 | 1 to 1x106 | 1 to 1x106 |

| Precision | measurement of value | ±0.1 % | ±0.1 % | ±0.1 % | ±0.1 % | ±0.1 % | ±0.1 % | ±0.1 % |

| Repeatability | ±0.01 % | ±0.01 % | ±0.01 % | ±0.01 % | ±0.01 % | ±0.01 % | ±0.01 % | |

| K-factor | K1 [P/I] | 1,216 | 640 | 234 | 71.0 | 39.8 | 16.8 | 8.8 |

| K2 [P/I] | 2,432 | 1,280 | 468 | 142 | 79.6 | 33.6 | 17.7 | |

| K3 [P/I] | 7,296 | 2,560 | 1,014 | 302 | 167 | 57.6 | 22.1 | |

| K4 [P/I] | 7,296 | 2,560 | 1,014 | 302 | 167 | 87.6 | 45.1 | |

| Frequency | f1 at Qnom [Hz] | 203 | 320 | 390 | 414 | 464 | 560 | 738 |

| f2 at Qnom [Hz] | 405 | 640 | 780 | 828 | 929 | 1,120 | 1,475 | |

| f3 at Qnom [Hz] | 1,216 | 1,280 | 1,690 | 1,760 | 1,949 | 1,920 | 1,842 | |

| f4 at Qnom [Hz] | 1,216 | 1,280 | 1,690 | 1,762 | 1,948 | 2,920 | 3,758 | |

| Sensor | BEG 06* / BEG 06A* | BEG 43D | BEG 44A | BEG 45 with BEV 13 | BEG 47D** / BEG 47E** | BEG 53A* / BEG 54A* | |

|---|---|---|---|---|---|---|---|

| Application | Ex-range | Standard | High pressure | High pressure, wide temperature range | Ex-range | Flow direction detection | |

| K-factor | K1 | K1 | K2 | K3 | K1 | K4 | |

| Signal | Namur | PNP | Push-Pull | PNP | Namur | Push-Pull | |

| Temperature | [°C] | -40 bis +150 | -40 to +150 | -40 to +200 | -40 to +250 | -25 (-40) to +150 | -40 to +150 |

| Max. pressure | [bar] | 350 | 250 | 420 | 420 | 40 | 650 |

| *dependent on nominal diameter | **dependent on temperature | ||||||