KRAL Processing Unit Smart Solution.

Measured value acquisition made easy, integration into monitoring systems via Modbus.

A compact processing unit combined with KRAL flowmeters.

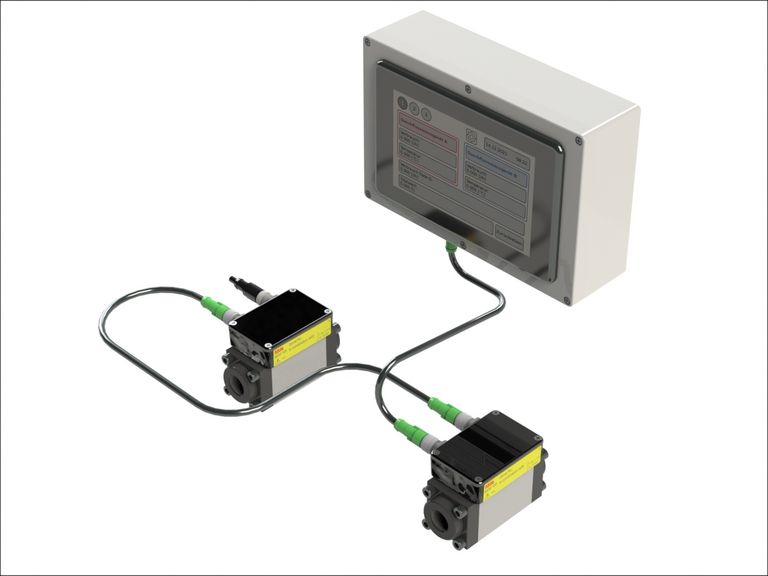

The Smart Solution is a compact processing unit to which a KRAL flowmeter is connected. The way the Smart Solution processes the signals the KRAL flowmeter generates with its integrated sensors ensures measured values are available that can be passed on via the Modbus. Up to 32 KRAL Smart Solution processing unit can be switched in series and thus save a multitude of cabling and their installation in comparison to conventional measured data acquisition.

For single-line and differential measurement of a maximum of two processing units, the KRAL Smart Solution Display can be used as an option.

Your advantages.

- Recording and evaluation of flow rate, flow direction and temperature

- Compensation of volume based on temperature and return flows during pulsations

- Calculation of mass of flow rate and consumption

- Input of 7 calibration points possible (linearization)

- Simple installation with only one cable between the flowmeters

- Information from up to 32 flowmeters can be called up via only one cable

Your advantages.

- Evaluation of 2 sensor signals for detection of of the flow direction possible.

- Temperature and pressure pulse compensation.

- Mass conversion.

- Easy installation with only one cable.

- Use of the full performance of the KRAL flowmeters.

- High-quality electronic components and evaluation algorithms.

- Clear, easy-to-read display.

- Up to 4 languages to choose from.

- Custom setting options.

Technical data.

| Size | 7 inch |

| Number of devices | Max. 2 processing units |

| Power supply | 19-30 V DC |

| Operating temperature | 0 °C to +60 °C |

| Degree of protection | IP65 |

| Interface | RS 485 |

| Suitable for Smart Solution | BEM 100, BEM 150 |

| Bus output | Modbus RTU |

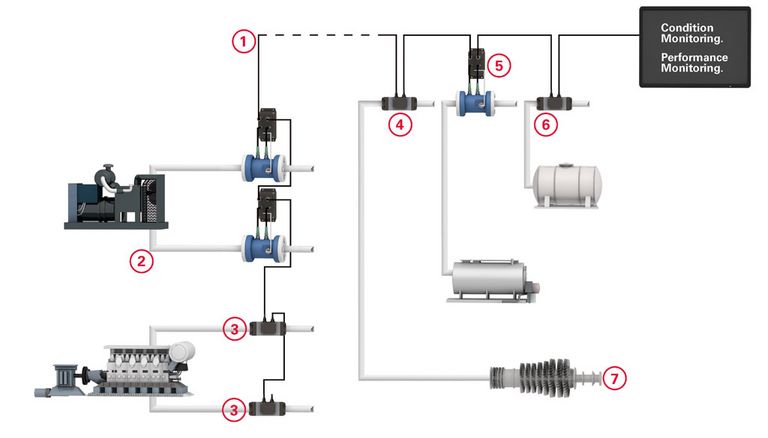

Up to 32 Smart Solution processing units.

Up to 32 Smart Solution processing units.

32 Smart Solution processing units can be switched in series and thus save a multitude of cabling and their installation in comparison to conventional measured data acquisition.

Differential measurement.

Differential measurement.

For differential measurement, two KRAL flowmeters are used per consumer (motor, generator, boiler, etc.). The difference between flow and return flow is the fuel consumption.

Temperature 1 and 2.

Temperature 1 and 2.

The temperature of the fuel in the return line is often higher than in the flow line. KRAL flowmeters measure the temperatures of the flow and return lines and correct the measured value according to the medium.

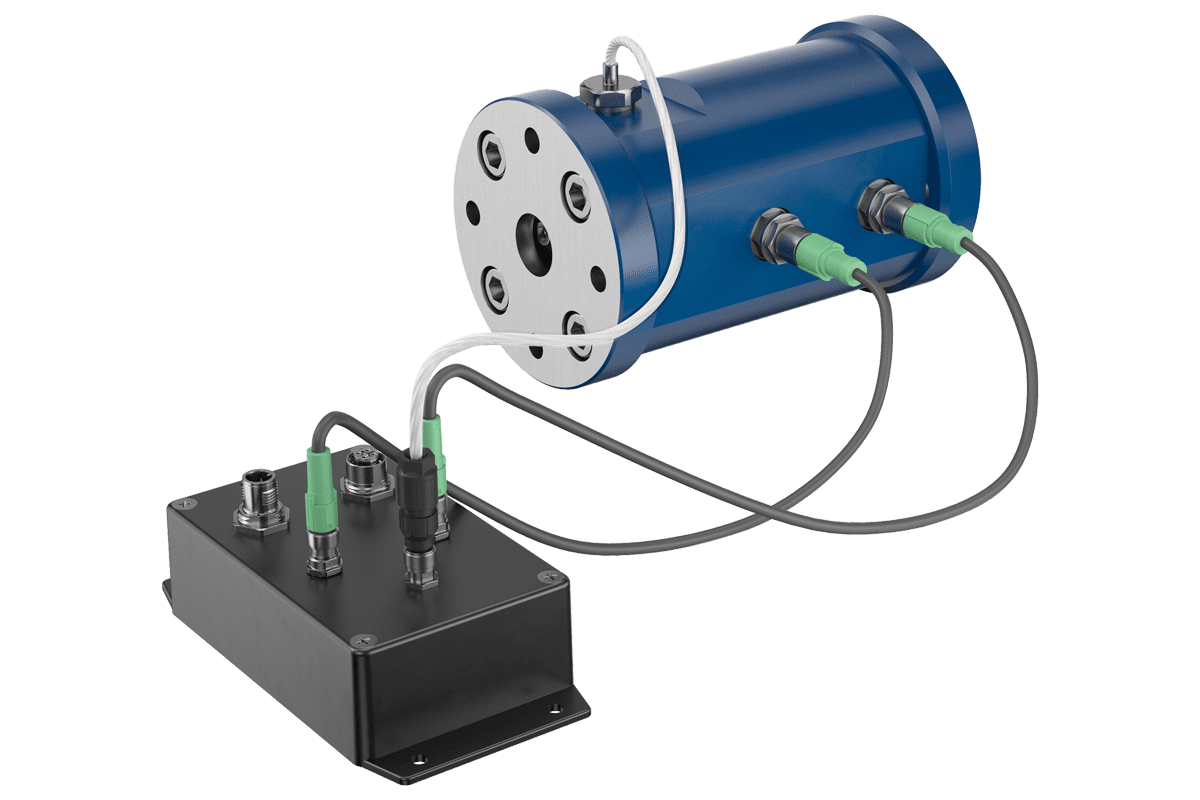

Smart Solution integrated into flowmeters.

Smart Solution integrated into flowmeters.

Pulse transmitter and temperature sensor are integrated into the flowmeter, the interfaces are directly connected to the Smart Solution processing unit. Power is supplied directly via the Modbus cable.

Smart Solution separated from flowmeter.

Smart Solution separated from flowmeter.

The pulse generator and temperature sensor are connected directly to the processing unit using plug connectors. Power is also supplied here via the Modbus cable.

Single line measurement.

Single line measurement.

In the simplest cases, a KRAL flowmeter is installed in front of the mixing tank.

Pulsations.

Pulsations.

Fuel does not always flow evenly through the pipes. It pulsates and can even change its flow direction. If this is not taken into consideration, the consumption value is incorrect. KRAL flowmeters measure in both directions. When using the second sensor for flow direction detection on the KRAL flowmeter, the return flows are detected and the measured value is corrected accordingly in the Smart Solution.