Net Positive Suction Head (NPSH).

What is NPSH?

In common parlance, we speak of the suction behavior of a pump, but the liquid is not sucked in but flows by itself from a high to a lower pressure level. The "suction" of the pump corresponds to the generation of a negative pressure at the pump inlet, whereby the liquid is forced into the pump, e.g. by atmospheric pressure.

If a pump could create absolute vacuum, it could raise a water column of 10.33 m due to the air pressure pb at sea level acting on the liquid level.

NPSHrequired is usually specified in mWC.

| Height above sea level [m] | Barometric pressure pb [bar] | Water column [mWC] |

| zero | 1.013 | 10.33 |

| 500 | 0.935 | 9.73 |

| 1000 | 0.899 | 9.16 |

| 2000 | 0.795 | 8.10 |

The NPSHrequired value of a pump is the minimum pressure required on the suction side of the pump to prevent cavitation.

NPSHr is determined in first approximation by the speed at which the medium must follow the receding screw flank. However, experiments have shown that the NPSHr of a screw pump is only dependent on the pump size (screw diameter), the speed and the viscosity of the pumped medium.

Thus the suction behaviour of a screw pump is described by the rotational speed and the axial speed of the flank, which in turn is directly dependent on the pitch of the screw.

Compared to other pump types, screw pumps have a very good suction performance. This can, for example, simplify work as a stripping pump of tanks etc., as air and other gases carried along can be admitted without a vapour barrier.

What is cavitation?

Cavitation occurs at any point in a pump if the pressure there is lower than the vapour pressure of the liquid. If the pressure at the pump inlet falls below the vapour pressure of the liquid, small vapour bubbles are formed. These bubbles burst (implode) when the pressure rises again, causing shock waves. Implosions can lead to material detachment and thus to damage to the housing and the screws. Cavitation also reduces the flow rate, which reduces the pump's performance. Cavitation also causes increased noise and vibration, which in turn can damage bearings, shaft seals and welds.

Available NPSH versus required NPSH.

In connection with NPSH calculations, two values are particularly important:

NPSHrequired: pressure head required by the pump. The NPSHr by the pump can be taken from the manufacturer's documentation or the pump design program.

NPSHavailable: The available pressure head of the system. This is system-specific and must be calculated individually for each system.

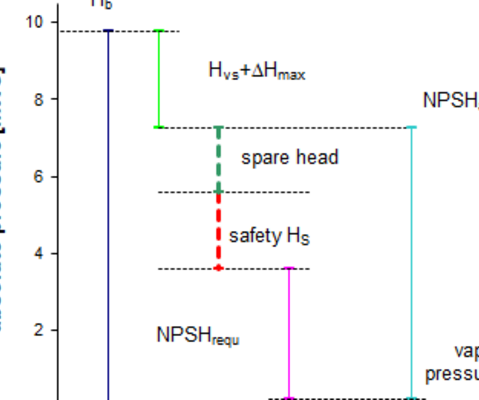

The NPSH value of the system (NPSHa) should be at least 0.5 m higher than the NPSH value of the pump (NPSHr).

NPSHa ≥ NPSHr + 0.5 m

Legend:

Hb – absolute pressure.

HVS - flow losses. Losses occur in the suction line due to the generation of velocity, liquid friction, changes in direction and cross section.

Hmax - maximum permissible geodetic suction head. Height difference between the surface of the suction-side liquid level (minimum tank level) and the center of the pump inlet cross section.

HS - Safety factor. This depends on the situation and usually varies between 0.5 m and 1 m. For liquids with a high gas content, a safety factor of up to 2 m must be taken into account.

HD - vapour pressure of the liquid. Liquids evaporate when the temperature-dependent vapour pressure is reached. At the highest point of the suctioned liquid column the pressure can only drop to this value.

17.09.2020