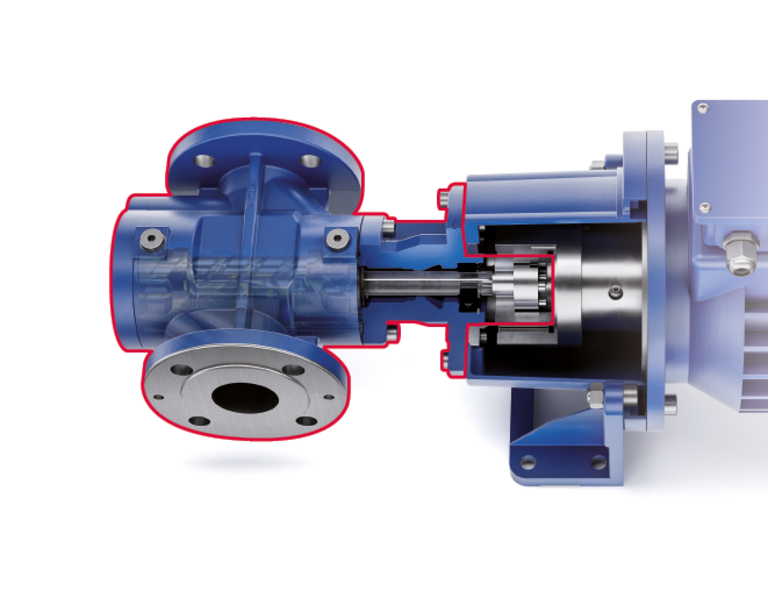

Magnetic Coupling 100 % Leak-free.

Magnetic coupling 100 % leak-free.

The times, they are changing. Safety has top priority, but at the same time, costs need to be as low as possible. Usually, it is one or the other, but with magnetic coupling, this combination has succeeded. When using 3-spindle pumps, you know that sooner or later there will be leaking shaft seals. KRAL has found the solution for this problem by magnetic coupling. With a mechanical seal, a small leak would rapidly lead to a massive flow, causing a quite a mess. With magnetic coupling this is no longer the case.

Mechanical sealing.

First, let’s see how mechanical seals work. One seal is rotating with the shaft, the other seal is stationary within the house. Between these two seals, there is a tiny leakage in order to create a hydrodynamic layer. With a functional pump this tiny leakage is perfectly okay as the fluid will vaporize. However, with fluids that do not vaporize quickly, like oil, for instance, causes the area around the sealing to become greasy. If the mechanical sealing is no longer leak-free, causing a messy leakage, the seals need to be replaced. Therefore several heavy components need to be dismounted which makes it a costly and time consuming exercise.

Magnetic coupling.

Magnetic coupling works substantially better because the two shafts are no longer mechanically sealed. The fluid is captured within the metal casing and there are no more rotating seals. This technique has been around much longer, but the costs for magnets have significantly decreased over the past couple of year, making it a profitable investment.

Advantages of magnetic coupling.

The magnetic coupling ensures that the maintenance of 3-spindle pumps is no longer necessary and the hazard of mechanical seal leakage vanishes. It leads to a clean engine room. The reliability of the pump increases a lot, meaning a much lower maintenance frequency. Furthermore, because HFO-oil is much signifficantly heated at extremely high temperatures, there’s a leakage-fire hazard. But because of the magnetic coupling, all oil will stay within the pump casing and fuels will no longer be able to exit the house. This increases safety immensely. Besides, because of the lower maintenance frequency and no need for spare parts, magnetic coupling also leads to overall cost reduction.

Cost reduction.

The initial investment when choosing magnetic coupling over mechanical sealing increases. However, running costs will decrease substantially. So much so that the extra investment will be earned back in 3 to 5 years, obviously depending on the number of seals that would have been replaced otherwise. Calculations show that the replacement of roughly three mechanical seals is equivalent to the extra investment costs of one magnetic coupling pump. Total ownership costs will be much lower with magnetic coupling instead of mechanical sealing pumps.

05.02.2020